Choosing the right chain lubricant

Home

Inspiration

Choosing the right chain lubricant

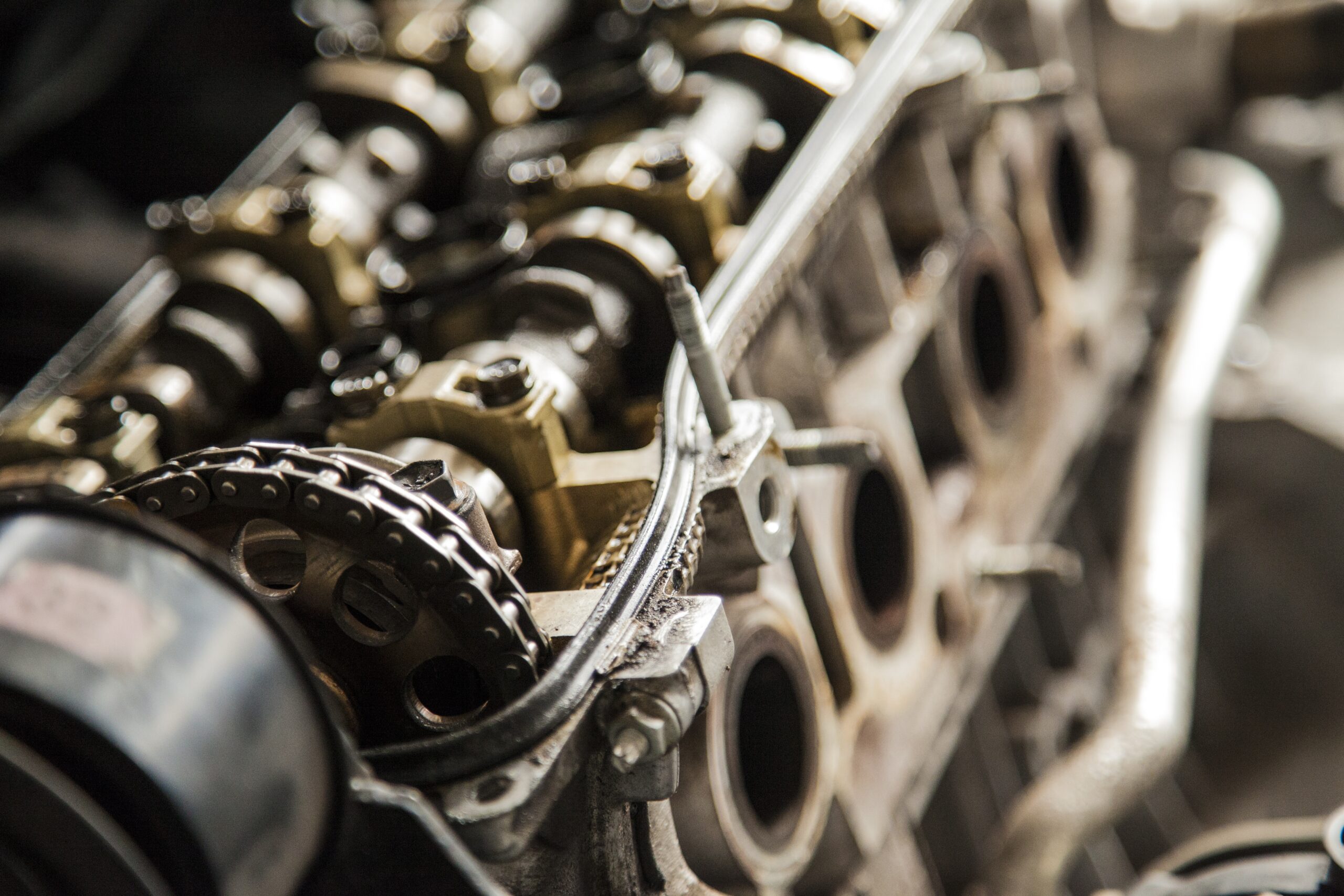

Chains play a crucial role in the smooth operation of various machines, from motorcycles and bicycles to chainsaws and industrial equipment. Understanding the different types of chains and their specific lubrication needs is essential to prevent common causes of failure, such as rust, wear, and friction. We’ll explore the different types of lubricant and the role they play in ensuring longevity and optimal performance for your gear.

Protecting chains from rust

Let’s look at what properly formulated chain oil should do. Firstly, it must help protect the chain from the most common cause of failure, which is rust. A carefully selected compound must be added that will enable lubricant to provide rust protection far beyond what it could do naturally and especially in those applications where moisture and humidity are present.

Minimizing Chain Wear

Another major cause of failure is excessive wear. Oil by itself does provide limited wear protection and reduces friction, but, in today’s high-tech world, the pressures and speeds encountered require far greater wear protection. A jerky start on a production line or a motorcycle will frequently break down a regular oil film and cause either seizure or extraordinary wear.

Additives must be chosen that can prevent this. The right compounds can easily triple the film strength of regular lubricants and provide reliable protection under extreme conditions.

The Right Viscosity Base Oil

Viscosity is what prevents the lubricant from either flying off the chain or just turning into a gluey mess. It’s important that the oil selected for the base lube must have the right viscosity. If it’s too thick, then extra power or fuel is needed to get it up to the desired speed. If it is too thin, then it can fly off the chain too easily and create a mess. After the correct viscosity oil is selected a small amount of tackiness additive should be included. This helps the lubricant stay in place and reduces any fly off, even at higher speeds.

Performance in Low Temperatures

Many petroleum base lubricants do not perform well at low temperatures as they tend to thicken or even harden to a solid like candle wax. Oils that can perform at temperatures well below zero are essential in colder areas. Much care should be taken in selecting the right base oil to make sure low temperature performance is possible.

Oxidizing Effects of Heat

Most people think refined petroleum oils are stable and never change — not so. Put a pure paraffinic high quality base oil in a pan and put it in the oven for a few weeks and you will begin to see it changing color — eventually becoming black tar.

This is caused by oxidation, which is accelerated by heat. Fortunately, science has discovered chemicals that protect the oil from oxidation and let them retain their beneficial characteristics. If chain oil is subjected to any type of heat, then oxidation is certain to follow unless it is protected by special additives.

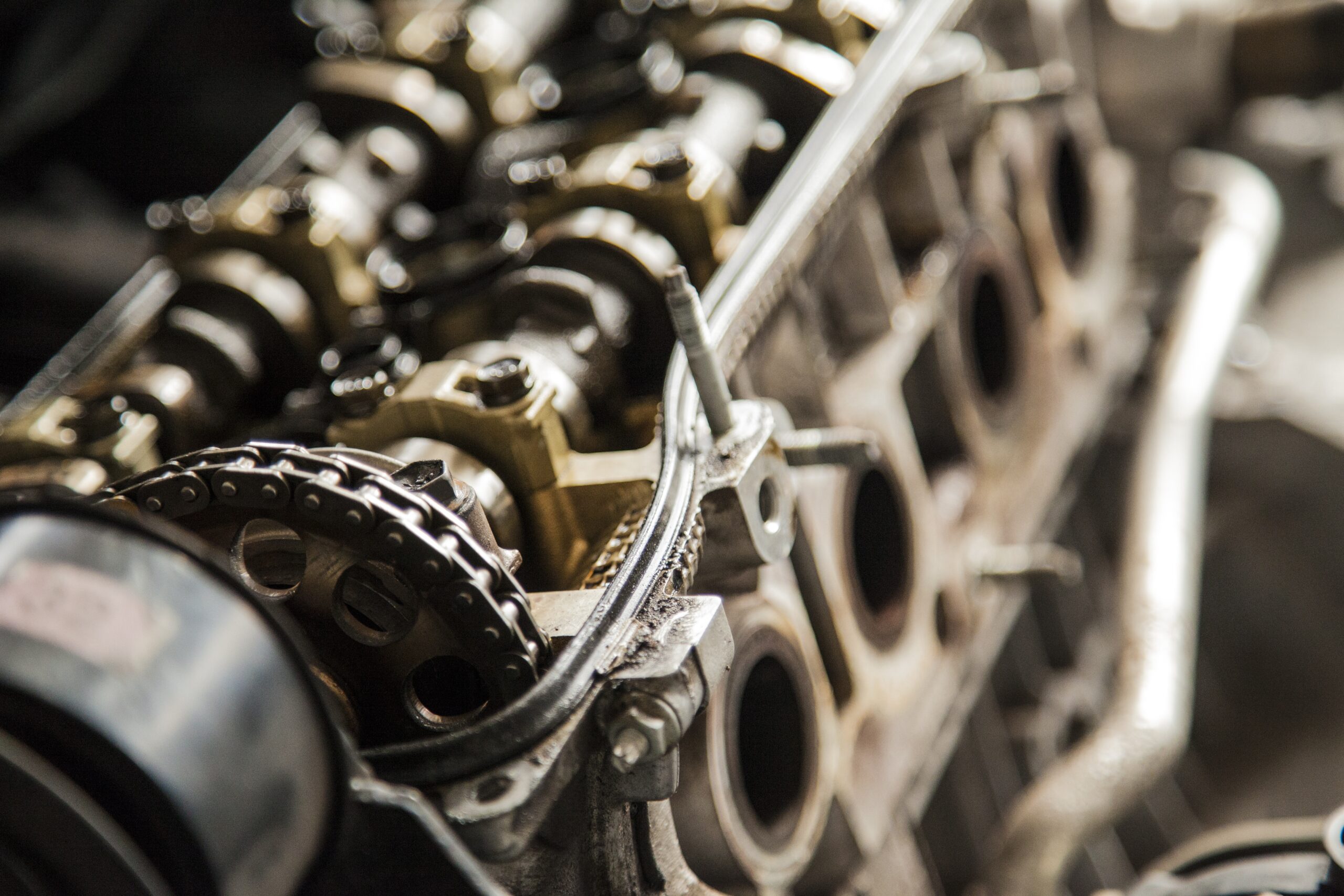

Industrial-Grade Lubricants

Protect All Chain Life® has been the industry standard in extreme pressure lubrication. Chain Life® penetrates, clings and silences chains while repelling dirt, sand, mud and grass. It is an excellent compound for lubrication. Chain Life® is a unique foaming lubricant that starts where oil leaves off. It applies as a bead of foam thus eliminating overspray and waste. It leaves a thin thermally stable film of extreme pressure lubricant that provides a barrier between moving metal parts, preventing metal to metal contact under heat and pressure.

Chain Life®

Thermally-stable lubricant that reduces surface scarring

SKU: 35017PA

Silicone and graphite-free lubricant formulated to prevent metal to metal contact under high heat and pressure. Coats the surface with a thin, thermally-stable film.